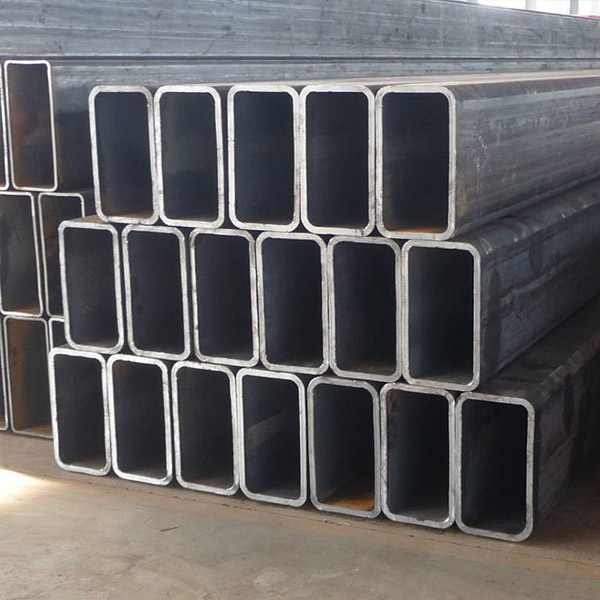

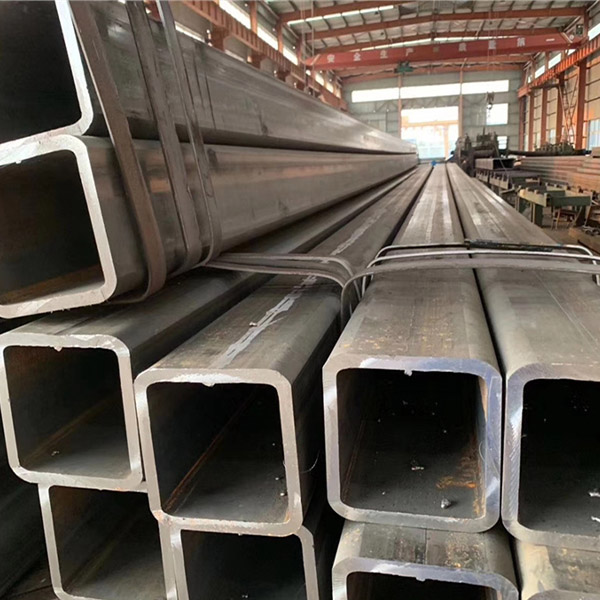

Welded Square Tube

ṣe lati orilẹ-ede Ṣaina

Ohun elo: tube igbomikana,

Boya opo gigun ti epo ti wa ni asopọ pẹlu alloy: ti kii ṣe alloy

Apẹrẹ apakan: square

tube pataki: API

tube sisanra: 1.5-60

Itọju oju: awọ dudu

Ifarada: ± 1%

Awọn iṣẹ ṣiṣe: atunse, alurinmorin, punching, gige

Ohun elo: Q195/Q215/Q235/Q345/10#/20#

Dada: dudu sokiri kun

Apẹrẹ: tube onigun

Iṣakojọpọ: iṣakojọpọ boṣewa

Awọn ọrọ-ọrọ: paipu irin ti ko ni oju

Akoko ifijiṣẹ: 7-15 ọjọ

Inu apẹrẹ paipu irin: dudu ṣofo apakan

Opoiye ibere ti o kere julọ: 1 pupọ

Idi: Ilana ile

ọna ẹrọ: Hot Rolling

Ijeri: API

1. Welded square tube ni a ṣofo square apakan, irin square tube, tun mo bi ṣofo tutu-akoso irin. O ti ṣe agbekalẹ nipasẹ titẹ tutu ati alurinmorin igbohunsafẹfẹ giga lẹhin ti yiyi-gbona tabi ṣiṣan tutu-yiyi tabi okun bi òfo Irin Ti a ṣe apẹrẹ pẹlu apẹrẹ agbelebu-apakan onigun mẹrin ati iwọn.

Ni afikun si sisanra ti sisanra ogiri ti tube square ti o nipọn, iwọn igun ati filati eti de ọdọ tabi kọja ipele ti resistance welded tutu-fọọmu square tube. Awọn iwọn ti awọn R igun ni gbogbo laarin 2 igba ati 3 igba odi sisanra. .Ni ibamu si awọn aini awọn onibara, a tun le gbe awọn tubes square R-angle ti iwọn ti awọn onibara nilo;

2. Square tube Seamless square tube jẹ gigun irin gigun pẹlu apakan ṣofo ati pe ko si awọn isẹpo lori ẹba. O ti wa ni a square tube akoso nipa extruding a seamless tube nipasẹ 4 mejeji ti a m. Awọn onigun tube ni o ni a ṣofo apakan ati ki o ti lo ni titobi nla. O ti wa ni lo ninu omi gbigbe, eefun ti support, darí be, alabọde ati kekere titẹ, ga titẹ igbomikana tube, ooru paṣipaarọ tube, gaasi, epo ati awọn miiran ise. O ti wa ni okun sii ju welded ati ki o yoo ko kiraki.

1. Ṣiṣan ilana ti tube digi imototo:

Tube òfo-iyẹwo-peeling-inspection-alapapo-perforation-pickling-lilọ-lubrication ati air gbígbẹ-alurinmorin ori-tutu iyaworan-ojutu itọju-pickling-pickling Passivation-iyẹwo-tutu sẹsẹ-degreasing-gige-air gbígbẹ-ti inu didan. - didan ita-ayẹwo-siṣamisi-ti pari ọja.

2. Ilana paipu ile-iṣẹ

Tube òfo-iyẹwo-peeling-inspection-heating-perforation-pickling-grinding-lubrication ati air drying-welding head-tutu iyaworan-ojutu itọju-pickling-pickling Passivation-inspection.

3. Ṣiṣan ilana ti paipu welded

Uncoiling-leveling-opin irẹrun ati alurinmorin-loooper-forming-welding-inner and lode bead yiyọ-ṣaaju-atunṣe-induction itọju ooru-iwọn ati titọ-eddy idanwo-gige lọwọlọwọ ——Ayẹwo titẹ agbara Hydraulic——Pickling——Ayẹwo ikẹhin —— Iṣakojọpọ.

4. Lainidi square tube ilana

Yika irin-tube billet-iyẹwo-alapapo-lilu-iwọn-gbona yiyi-flat ori-iyẹwo-pickling-spherical annealing-tutu iyaworan-didara-Qikou- -idanwo

Q345A: C≤0.20, Mn ≤1.70, Si≤0.50, P≤0.035, S≤0.035;

Q345B: C≤0.20, Mn ≤1.70, Si≤0.50, P≤0.035, S≤0.035;

Q345C: C≤0.20,Mn

Q345D: C≤0.18,Mn

Q345E: C≤0.18, Mn ≤1.70, Si≤0.50, P≤0.025, S≤0.020, Al≥0.015;

Q345A, B, C, D, E Nb≤0.07,V≤0.15,Ti≤0.20,Cr≤0.30,N≤0.012,Mo≤0.10. 20#, Q235B

| Tabili paipu onigun mẹrin ti o nipọn (mm) | Tabili paipu onigun onigun ti o nipọn (mm) | ||

| 16 ~ 34×0.4~2.0 | 380 ~ 500× 380 ~ 500×8.0~30.0 | 10 ~ 20× 20 ~ 40× 0.6 ~ 12.0 | 250~300×100~250×6~30.0 |

| 16 ~ 34×0.4~2.0 | Miiran redraw sipesifikesonu jẹ bi wọnyi | 20× 50× 1.0~2.0 | 400×250×8~30.0 |

| 38× 38× 1.0 ~ 4.0 | 550× 550× 10.0 ~ 40.0 | 22~40×35~100×0.9~5.0 | 400~×300×8~30.0 |

| 40~95×40~95×1.0~8.0 | 600~1000×600~1000×10.0~50.0 | 25×40×0.9~3.75 | 450~500×200~450×8~30.0 |

| 100×100×2.0~8.0 | 50× 60×2.0~5.0 | Miiran redraw sipesifikesonu jẹ bi wọnyi | |

| 120~350×120~350×4.0~30.0 | 50 ~ 200× 60 ~ 150× 2.0~12.0 | 600~1000×200~800×10~28.0 | |